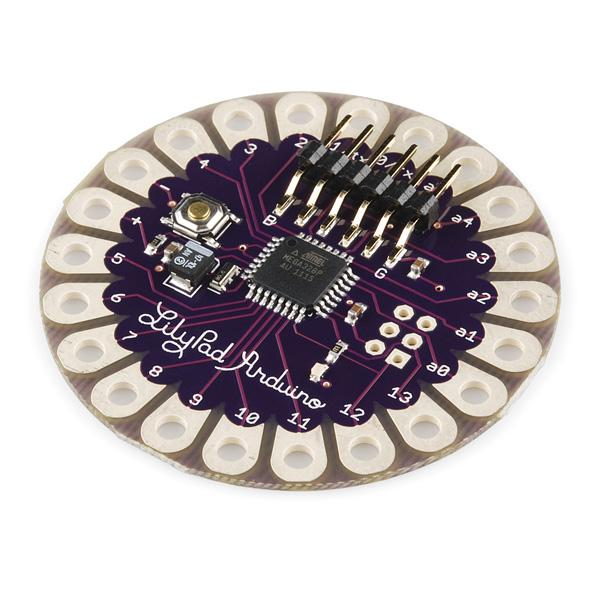

In my eternal quest for finding possible projects I thought there would be no better way to get into the Lilly-pad (and this is meant to be slightly ironic), than to mess with a slightly finicky hear sensor and even harder to time Adafruit Neopixel rings,

Like the emotionally unstable crazy person that I am, I decided I should find a way to show people what emotion I'm most likely experiencing. I had access to a hear rate sensor and since you can actually mount those as an ear ring, it serves my needs perfectly.

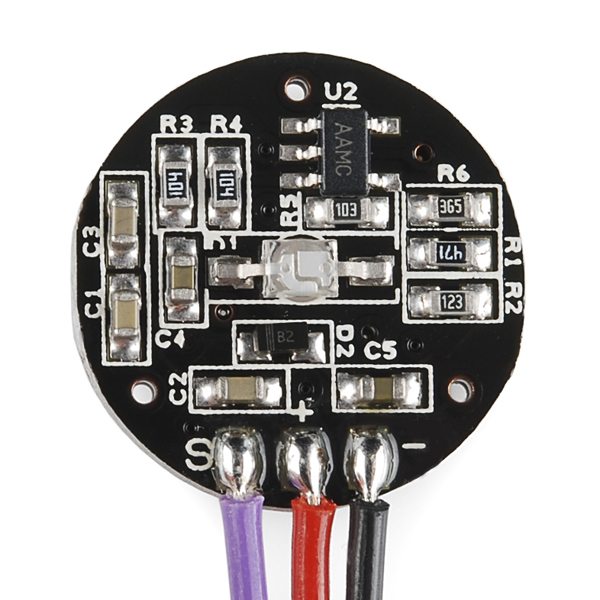

So first of all lets talk about how the pulse sensor works. If we look at the diagram above we an see that we simply have an LED going through a small circuit to a Photo-resistor. The Photo-resistor takes the amount of light present and turns it into an Analog Voltage. When blood is pumped through your finger or ear there is a difference in the amount of light. Through code we can actually get this simple sensor to act as a fairly sensitive heartbeat monitor. Plus, who doesn't want their ears to glow green?!

So next we need to see how we can actually show our emotions from our heart beat. And of course the first thing that comes to mind are individually addressable LED strips, the Adafruit Neopixel rings are perfect for the job!

Important Things to Know About NeoPixels in General

- Not all addressable LEDs are NeoPixels. “NeoPixel” is Adafruit’s brand for individually-addressable RGB color pixels and strips based on the WS2812 and WS2811 LED/drivers, using a single-wire control protocol. Other LED products we carry — WS2801 pixels, LPD8806 and “analog” strips — use different methodologies (and have their own tutorials). When seeking technical support in the forums, a solution can be found more quickly if the correct LED type is mentioned.

- NeoPixels don’t just light up on their own; they require a microcontroller (such as Arduino) and some programming. (Just giving them power will not make them turn on)

- NeoPixels aren’t the answer for every project. The control signal has very strict timing requirements, and some development boards (such as Netduino or Raspberry Pi) can’t reliably achieve this. This is why we continue to offer other LED types; some are more adaptable to certain situations.

The approximate peak power use (all LEDs on at maximum brightness) per meter is:

- 30 LEDs: 9.5 Watts (just under 2 Amps at 5 Volts).

- 60 LEDs: 18 Watts (about 3.6 Amps at 5 Volts).

- 144 LEDs : 35 watts (7 Amps at 5 Volts).

So the plan here is to have the Neopixel Rings light up to the rhythm of your heart. The plan is also to have it change colors if its within certain BPM (beats per minutes) ranges. A possible addition would be to have more and more Neopixels light up as your heart beats faster but this would results in the LEDs

The code will be something similar to this, timing needs to be adjusted however:

/*

>>> Pulse Sensor purple wire goes to Analog Pin 0 by default <<<

Pulse Sensor Power and GND wires go to a Digital Pin set High and to the Ground Plane of the PCB.

Pulse Sensor sample aquisition and processing happens in the background via Timer 2 interrupt. 2mS sample rate.

PWM on pins 3 and 11 will not work when using this code, because we are using Timer 2!

The following variables are automatically updated:

Signal : int that holds the analog signal data straight from the sensor. updated every 2mS.

IBI : int that holds the time interval between beats. 2mS resolution.

BPM : int that holds the heart rate value, derived every beat, from averaging previous 10 IBI values.

QS : boolean that is made true whenever Pulse is found and BPM is updated. User must reset.

Pulse : boolean that is true when a heartbeat is sensed then false in time with pin13 LED going out.

NeoPixel Ring goggles sketch -- Andrei Aldea 2014

Welding goggles using 50mm round lenses can be outfitted with

a pair of Adafruit NeoPixel Rings

By default, pixel #0 (the first LED) on both rings should be at the TOP of

the goggles. Looking at the BACK of the board, pixel #0 is immediately

clockwise from the OUT connection. If a different pixel is at the top,

that's OK, the code can compensate (TOP_LED_FIRST and TOP_LED_SECOND below).

IMPORTANT: To reduce NeoPixel burnout risk, add 1000 uF capacitor across

pixel power leads, add 300 - 500 Ohm resistor on first pixel's data input

and minimize distance between Arduino and first pixel. Avoid connecting

on a live circuit...if you must, connect GND first.

*/

#include <Adafruit_NeoPixel.h>

#ifdef __AVR_ATtiny85__ // Trinket, Gemma or other ATtiny type devices

#include <avr/power.h>

#endif

#define PIN 0

#define TOP_LED_FIRST 0 // Change these if the first pixel is not

#define TOP_LED_SECOND 0 // at the top of the first and/or second ring.

#define EFFECT RAINBOW // Choose a visual effect from the names below

#define RAINBOW 0

#define ECTO 1

Adafruit_NeoPixel pixels = Adafruit_NeoPixel(32, PIN, NEO_GRB + NEO_KHZ800);

const int8_t PROGMEM

yCoord[] = { // Vertical coordinate of each pixel. First pixel is at top.

127,117,90,49,0,-49,-90,-117,-127,-117,-90,-49,0,49,90,117 }

,

sine[] = { // Brightness table for ecto effect

0, 28, 96, 164, 192, 164, 96, 28, 0, 28, 96, 164, 192, 164, 96, 28 };

// Eyelid vertical coordinates. Eyes shut slightly below center.

#define upperLidTop 130

#define upperLidBottom -45

#define lowerLidTop -40

#define lowerLidBottom -130

const uint8_t PROGMEM gamma8[] = {

0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0, 0,

0, 0, 0, 0, 0, 0, 0, 0, 1, 1, 1, 1, 1, 1, 1, 1,

1, 1, 1, 1, 2, 2, 2, 2, 2, 2, 2, 2, 3, 3, 3, 3,

3, 3, 4, 4, 4, 4, 5, 5, 5, 5, 5, 6, 6, 6, 6, 7,

7, 7, 8, 8, 8, 9, 9, 9, 10, 10, 10, 11, 11, 11, 12, 12,

13, 13, 13, 14, 14, 15, 15, 16, 16, 17, 17, 18, 18, 19, 19, 20,

20, 21, 21, 22, 22, 23, 24, 24, 25, 25, 26, 27, 27, 28, 29, 29,

30, 31, 31, 32, 33, 34, 34, 35, 36, 37, 38, 38, 39, 40, 41, 42,

42, 43, 44, 45, 46, 47, 48, 49, 50, 51, 52, 53, 54, 55, 56, 57,

58, 59, 60, 61, 62, 63, 64, 65, 66, 68, 69, 70, 71, 72, 73, 75,

76, 77, 78, 80, 81, 82, 84, 85, 86, 88, 89, 90, 92, 93, 94, 96,

97, 99,100,102,103,105,106,108,109,111,112,114,115,117,119,120,

122,124,125,127,129,130,132,134,136,137,139,141,143,145,146,148,

150,152,154,156,158,160,162,164,166,168,170,172,174,176,178,180,

182,184,186,188,191,193,195,197,199,202,204,206,209,211,213,215,

218,220,223,225,227,230,232,235,237,240,242,245,247,250,252,255

};

uint32_t

iColor[16][3]; // Background colors for eyes

int16_t

hue = 0; // Initial hue around perimeter (0-1535)

uint8_t

iBrightness[16], // Brightness map -- eye colors get scaled by these

brightness = 220, // Global brightness (0-255)

blinkFrames = 5, // Speed of current blink

blinkCounter = 30, // Countdown to end of next blink

eyePos = 192, // Current 'resting' eye (pupil) position

newEyePos = 192, // Next eye position when in motion

gazeCounter = 75, // Countdown to next eye movement

gazeFrames = 50; // Duration of eye movement (smaller = faster)

int8_t

eyeMotion = 0; // Distance from prior to new position

// VARIABLES

int pulsePin = 0; // Pulse Sensor purple wire connected to analog pin 0

int blinkPin = 13; // pin to blink led at each beat

int fadePin = 5; // pin to do fancy classy fading blink at each beat

int fadeRate = 0; // used to fade LED on with PWM on fadePin

// these variables are volatile because they are used during the interrupt service routine!

volatile int BPM; // used to hold the pulse rate

volatile int Signal; // holds the incoming raw data

volatile int IBI = 600; // holds the time between beats, must be seeded!

volatile boolean Pulse = false; // true when pulse wave is high, false when it's low

volatile boolean QS = false; // becomes true when Arduoino finds a beat.

//====================================START OF VOID SETUP==============================================

void setup(){

pinMode(blinkPin,OUTPUT); // pin that will blink to your heartbeat!

pinMode(fadePin,OUTPUT); // pin that will fade to your heartbeat!

Serial.begin(115200); // we agree to talk fast!

interruptSetup(); // sets up to read Pulse Sensor signal every 2mS

// UN-COMMENT THE NEXT LINE IF YOU ARE POWERING The Pulse Sensor AT LOW VOLTAGE,

// AND APPLY THAT VOLTAGE TO THE A-REF PIN

//analogReference(EXTERNAL);

#ifdef __AVR_ATtiny85__ // Trinket, Gemma, etc.

if(F_CPU == 16000000) clock_prescale_set(clock_div_1);

// Seed random number generator from an unused analog input:

randomSeed(analogRead(2));

#else

randomSeed(analogRead(A0));

#endif

pixels.begin();

}

//====================================START OF VOID LOOP===============================================

void loop(){

if (QS == true){ // Quantified Self flag is true when arduino finds a heartbeat

fadeRate = 255; // Set 'fadeRate' Variable to 255 to fade LED with pulse

//WRITE YOUR OTHER FUNCTIONS HERE FOR THE GOGGLES! You can use BPM or BPS as a variable here

QS = false; // reset the Quantified Self flag for next time

}

//=================================Start of Neopixel Effects===============================================

uint8_t i, r, g, b, a, c, inner, outer, ep;

int y1, y2, y3, y4, h;

int8_t y;

// Draw eye background colors

#if EFFECT == RAINBOW

// This renders a glotating rainbow...a WAY overdone LED effect but

// does show the color gamut nicely.

for(h=hue, i=0; i<16; i++, h += 96) {

a = h;

switch((h >> 8) % 6) {

case 0: iColor[i][0] = 255; iColor[i][1] = a; iColor[i][2] = 0; break;

case 1: iColor[i][0] = ~a; iColor[i][1] = 255; iColor[i][2] = 0; break;

case 2: iColor[i][0] = 0; iColor[i][1] = 255; iColor[i][2] = a; break;

case 3: iColor[i][0] = 0; iColor[i][1] = ~a; iColor[i][2] = 255; break;

case 4: iColor[i][0] = a; iColor[i][1] = 0; iColor[i][2] = 255; break;

case 5: iColor[i][0] = 255; iColor[i][1] = 0; iColor[i][2] = ~a; break;

}

}

hue += 7;

if(hue >= 1536) hue -= 1536;

#elif EFFECT == ECTO

// A steampunk aesthetic might fare better with this more subdued effect.

// Etherial green glow with just a little animation for visual spice.

a = (hue >> 4) & 15;

c = hue & 15;

for(i=0; i<16; i++) {

b = (a + 1) & 15;

iColor[i][1] = 255; // Predominantly green

iColor[i][0] = (pgm_read_byte(&sine[a]) * (16 - c) +

pgm_read_byte(&sine[b]) * c ) >> 4;

iColor[i][2] = iColor[i][0] >> 1;

a = b;

}

hue -= 3;

#endif

// Render current blink (if any) into brightness map

if(blinkCounter <= blinkFrames * 2) { // In mid-blink?

if(blinkCounter > blinkFrames) { // Eye closing

outer = blinkFrames * 2 - blinkCounter;

inner = outer + 1;

} else { // Eye opening

inner = blinkCounter;

outer = inner - 1;

}

y1 = upperLidTop - (upperLidTop - upperLidBottom) * outer / blinkFrames;

y2 = upperLidTop - (upperLidTop - upperLidBottom) * inner / blinkFrames;

y3 = lowerLidBottom + (lowerLidTop - lowerLidBottom) * inner / blinkFrames;

y4 = lowerLidBottom + (lowerLidTop - lowerLidBottom) * outer / blinkFrames;

for(i=0; i<16; i++) {

y = pgm_read_byte(&yCoord[i]);

if(y > y1) { // Above top lid

iBrightness[i] = 0;

} else if(y > y2) { // Blur edge of top lid in motion

iBrightness[i] = brightness * (y1 - y) / (y1 - y2);

} else if(y > y3) { // In eye

iBrightness[i] = brightness;

} else if(y > y4) { // Blur edge of bottom lid in motion

iBrightness[i] = brightness * (y - y4) / (y3 - y4);

} else { // Below bottom lid

iBrightness[i] = 0;

}

}

} else { // Not in blink -- set all 'on'

memset(iBrightness, brightness, sizeof(iBrightness));

}

if(--blinkCounter == 0) { // Init next blink?

blinkFrames = random(4, 8);

blinkCounter = blinkFrames * 2 + random(5, 180);

}

// Calculate current eye movement, possibly init next one

if(--gazeCounter <= gazeFrames) { // Is pupil in motion?

ep = newEyePos - eyeMotion * gazeCounter / gazeFrames; // Current pos.

if(gazeCounter == 0) { // Last frame?

eyePos = newEyePos; // Current position = new pos

newEyePos = random(16) * 16; // New pos. (always pixel center)

eyeMotion = newEyePos - eyePos; // Distance to move

gazeFrames = random(10, 20); // Duration of movement

gazeCounter = random(gazeFrames, 130); // Count to END of next movement

}

} else ep = eyePos; // Not moving -- fixed gaze

// Draw pupil -- 2 pixels wide, but sup-pixel positioning may span 3.

a = ep >> 4; // First candidate

b = (a + 1) & 0x0F; // 1 pixel CCW of a

c = (a + 2) & 0x0F; // 2 pixels CCW of a

i = ep & 0x0F; // Fraction of 'c' covered (0-15)

iBrightness[a] = (iBrightness[a] * i ) >> 4;

iBrightness[b] = 0;

iBrightness[c] = (iBrightness[c] * (16 - i)) >> 4;

// Merge iColor with iBrightness, issue to NeoPixels

for(i=0; i<16; i++) {

a = iBrightness[i] + 1;

// First eye

r = iColor[i][0]; // Initial background RGB color

g = iColor[i][1];

b = iColor[i][2];

if(a) {

r = (r * a) >> 8; // Scale by brightness map

g = (g * a) >> 8;

b = (b * a) >> 8;

}

pixels.setPixelColor(((i + TOP_LED_FIRST) & 15),

pgm_read_byte(&gamma8[r]), // Gamma correct and set pixel

pgm_read_byte(&gamma8[g]),

pgm_read_byte(&gamma8[b]));

// Second eye uses the same colors, but reflected horizontally.

// The same brightness map is used, but not reflected (same left/right)

r = iColor[15 - i][0];

g = iColor[15 - i][1];

b = iColor[15 - i][2];

if(a) {

r = (r * a) >> 8;

g = (g * a) >> 8;

b = (b * a) >> 8;

}

pixels.setPixelColor(16 + ((i + TOP_LED_SECOND) & 15),

pgm_read_byte(&gamma8[r]),

pgm_read_byte(&gamma8[g]),

pgm_read_byte(&gamma8[b]));

}

pixels.show();

delay(15);

}

//The interrups need to be set different for different AVR Microcontrollers, see code bellow

/*

The register settings above tell Timer2 to go into CTC mode, and to count up to 124 (0x7C) over and over and over again.

A prescaler of 256 is used to get the timing right so that it takes 2 milliseconds to count to 124.

An interrupt flag is set every time Timer2 reaches 124, and a special function called an Interrupt Service Routine (ISR) that we wrote is run at the very next possible moment, no matter what the rest of the program is doing. sei() ensures that global interrupts are enabled.

Timing is important! If you are using a different Arduino or Arduino compatible device, you will need to change this function. (please see different interrupts bellow)

This code works with Arduino UNO or Arduino PRO or Arduino Pro Mini 5V or any Arduino running with an ATmega328 and 16MHz clock.

void interruptSetup(){

TCCR2A = 0x02;

TCCR2B = 0x06;

OCR2A = 0x7C;

TIMSK2 = 0x02;

sei();

}

If you are using a FIO or LillyPad Arduino or Arduino Pro Mini 3V or Arduino SimpleSnap or other Arduino that has ATmega168 or ATmega328 with 8MHz oscillator, change the line TCCR2B = 0x06 to TCCR2B = 0x05.

If you are using Arduino Leonardo or Adafruit's Flora or Arduino Micro or other Arduino that has ATmega32u4 running at 16MHz

void interruptSetup(){

TCCR0A = 0x02;

TCCR0B = 0x04;

OCR0A = 0x7C;

TIMSK0 = 0x02;

sei();

}

The LilyPad Arduino USB runs at 8MHz, likely some other ATmega32u4 based devices out there, so to correct the timing, change TCCR0B = 0x04; to TCCR0B = 0x03; Then change OCR0A = 0x7C; to OCR0A = 0xF9;

The only other thing you will need is the correct ISR vector in the next step. ATmega32u4 devices use ISR(TIMER0_COMPA_vect)

*/

volatile int rate[10]; // array to hold last ten IBI values

volatile unsigned long sampleCounter = 0; // used to determine pulse timing

volatile unsigned long lastBeatTime = 0; // used to find IBI

volatile int P =512; // used to find peak in pulse wave, seeded

volatile int T = 512; // used to find trough in pulse wave, seeded

volatile int thresh = 512; // used to find instant moment of heart beat, seeded

volatile int amp = 100; // used to hold amplitude of pulse waveform, seeded

volatile boolean firstBeat = true; // used to seed rate array so we startup with reasonable BPM

volatile boolean secondBeat = false; // used to seed rate array so we startup with reasonable BPM

void interruptSetup(){

// Initializes Timer2 to throw an interrupt every 2mS.

TCCR2A = 0x02; // DISABLE PWM ON DIGITAL PINS 3 AND 11, AND GO INTO CTC MODE

TCCR2B = 0x05; // DON'T FORCE COMPARE, 256 PRESCALER

OCR2A = 0X7C; // SET THE TOP OF THE COUNT TO 124 FOR 500Hz SAMPLE RATE

TIMSK2 = 0x02; // ENABLE INTERRUPT ON MATCH BETWEEN TIMER2 AND OCR2A

sei(); // MAKE SURE GLOBAL INTERRUPTS ARE ENABLED

}

// THIS IS THE TIMER 2 INTERRUPT SERVICE ROUTINE.

// Timer 2 makes sure that we take a reading every 2 miliseconds

ISR(TIMER2_COMPA_vect){ // triggered when Timer2 counts to 124

cli(); // disable interrupts while we do this

Signal = analogRead(pulsePin); // read the Pulse Sensor

sampleCounter += 2; // keep track of the time in mS with this variable

int N = sampleCounter - lastBeatTime; // monitor the time since the last beat to avoid noise

// find the peak and trough of the pulse wave

if(Signal < thresh && N > (IBI/5)*3){ // avoid dichrotic noise by waiting 3/5 of last IBI

if (Signal < T){ // T is the trough

T = Signal; // keep track of lowest point in pulse wave

}

}

if(Signal > thresh && Signal > P){ // thresh condition helps avoid noise

P = Signal; // P is the peak

} // keep track of highest point in pulse wave

// NOW IT'S TIME TO LOOK FOR THE HEART BEAT

// signal surges up in value every time there is a pulse

if (N > 250){ // avoid high frequency noise

if ( (Signal > thresh) && (Pulse == false) && (N > (IBI/5)*3) ){

Pulse = true; // set the Pulse flag when we think there is a pulse

digitalWrite(blinkPin,HIGH); // turn on pin 13 LED

IBI = sampleCounter - lastBeatTime; // measure time between beats in mS

lastBeatTime = sampleCounter; // keep track of time for next pulse

if(secondBeat){ // if this is the second beat, if secondBeat == TRUE

secondBeat = false; // clear secondBeat flag

for(int i=0; i<=9; i++){ // seed the running total to get a realisitic BPM at startup

rate[i] = IBI;

}

}

if(firstBeat){ // if it's the first time we found a beat, if firstBeat == TRUE

firstBeat = false; // clear firstBeat flag

secondBeat = true; // set the second beat flag

sei(); // enable interrupts again

return; // IBI value is unreliable so discard it

}

// keep a running total of the last 10 IBI values

word runningTotal = 0; // clear the runningTotal variable

for(int i=0; i<=8; i++){ // shift data in the rate array

rate[i] = rate[i+1]; // and drop the oldest IBI value

runningTotal += rate[i]; // add up the 9 oldest IBI values

}

rate[9] = IBI; // add the latest IBI to the rate array

runningTotal += rate[9]; // add the latest IBI to runningTotal

runningTotal /= 10; // average the last 10 IBI values

BPM = 60000/runningTotal; // how many beats can fit into a minute? that's BPM!

QS = true; // set Quantified Self flag

// QS FLAG IS NOT CLEARED INSIDE THIS ISR

}

}

if (Signal < thresh && Pulse == true){ // when the values are going down, the beat is over

digitalWrite(blinkPin,LOW); // turn off pin 13 LED

Pulse = false; // reset the Pulse flag so we can do it again

amp = P - T; // get amplitude of the pulse wave

thresh = amp/2 + T; // set thresh at 50% of the amplitude

P = thresh; // reset these for next time

T = thresh;

}

if (N > 2500){ // if 2.5 seconds go by without a beat

thresh = 512; // set thresh default

P = 512; // set P default

T = 512; // set T default

lastBeatTime = sampleCounter; // bring the lastBeatTime up to date

firstBeat = true; // set these to avoid noise

secondBeat = false; // when we get the heartbeat back

}

sei(); // enable interrupts when you're done!

}// end isr

This project will be continued over the summer, however, due to time and material restraints, I am not able to work on it further at this time. Please stand by for a full tutorial sometime this summer.